Pasta production is a complex and involved process based on several mandatory steps. Regardless of the flour used—wheat, corn, or rice—the overall production process is consistent and well-coordinated.

Pasta Production Features

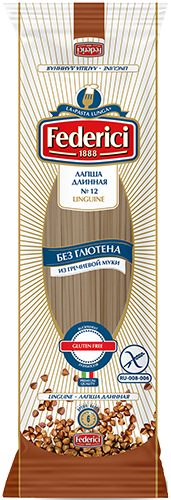

Our online store offers pasta produced under the renowned Italian brand Federici in accordance with international quality standards. Using modern pasta production technology, we can produce pasta with a wide variety of textures and colors. We produce many types of pasta, including:

- tubular;

- shaped;

- thread-shaped;

- ribbon-shaped.

Various pasta production technologies are used on our integrated mechanized production lines. This allows the finished product to be short, short-cut, stamped, or extruded. Modern production is characterized by a high degree of mechanization, high productivity, and process flexibility.

Pasta production utilizes equipment such as dies, specialized cutting mechanisms, stamping machines, screw presses, machines for cutting finished products, and others. The dies and pressing devices are the primary production units. The die directly influences press performance, product shape and size, and pasta quality.

Raw Material and Product Requirements

The main ingredients used in the production of any pasta product are flour, water, and salt. Premium pasta has an amber-yellow or straw-yellow color. It is made from a special flour called semolina, which is a byproduct of grinding hard or softer vitreous wheat grains. First-grade flour—semi-semolina of hard or soft vitreous wheat—produces products with a light brownish tint. The main quality indicators of flour used for pasta are:

- color;

- quantitative and qualitative gluten levels;

- particle size.

Raw materials with a low gluten content produce extremely fragile products that quickly break and crumble into small pieces. The quality of raw gluten should not be lower than Group II. Serve flour, which absorbs water very slowly and forms a flexible dough, is considered the most valuable in this regard. Pasta flour should not contain large amounts of the following components:

Raw materials with a low gluten content produce extremely fragile products that quickly break and crumble into small pieces. The quality of raw gluten should not be lower than Group II. Serve flour, which absorbs water very slowly and forms a flexible dough, is considered the most valuable in this regard. Pasta flour should not contain large amounts of the following components:

- free amino acids;

- reducing sugars;

- active polyphenol oxidase (tyrosinase).

Water used for pasta production should have moderate hardness and meet all GOST drinking water requirements. Surface-active agents (surfactants) help improve the appearance and taste of pasta. Their main role is to ensure maximum shape retention during cooking and prevent sticking. The quality of the finished pasta is equally affected by the manufacturing process itself.

Pasta Production Technology

Modern pasta-making technologies, a comprehensive range of recipes, and only the finest raw materials—this approach allows us to produce a wide range of high-quality pasta products to suit every taste. Pasta production consists of several operations that require a responsible and well-coordinated approach:

- raw material preparation;

- pasta dough preparation;

- dough pressing;

- cutting raw products;

- drying;

- cooling dried products;

- rejecting defective products;

- packaging finished products.

The raw material preparation process includes sifting flour and separating various impurities, then heating and mixing the raw materials in the required proportions. Water is then heated in heat exchangers and combined with cold tap water to the required temperature. Pasta dough preparation involves dosing the ingredients—flour, water, and various additives—and kneading the dough.

The main purpose of pressing the dough is to compact it and transform it into a homogeneous, plastic mass. After this, it can be shaped into any desired shape by pressing the dough through holes in a special metal die. Cutting raw pasta is necessary to obtain pieces of the desired length and prepare them for further drying.

The main purpose of pressing the dough is to compact it and transform it into a homogeneous, plastic mass. After this, it can be shaped into any desired shape by pressing the dough through holes in a special metal die. Cutting raw pasta is necessary to obtain pieces of the desired length and prepare them for further drying.

Drying helps to establish the desired shape and prevents the further development of various microorganisms. Drying is the longest and most important stage of the entire technological process. At this stage, it is important to understand that excessive drying can cause unwanted cracks in the pasta, while slow or insufficient drying can lead to souring. The best option is modern convective drying, which achieves the desired result by blowing heated air onto the product.

Cooling normalizes the high temperature of the finished products after drying. This process takes place in special chambers and bins – stabilizers and accumulators. After selecting defective products from the batch, the finished pasta is packaged in suitable containers – bags, paper boxes, cartons, etc.

Leading-edge production equipment

The pasta production technology at the Ameria factory is based on the invaluable experience of our employees and the constant implementation of creative approaches. A clearly defined process and the use of cutting-edge technologies ensure that we produce only the highest quality finished products.

We use only premium or first-grade flour, guaranteeing that our finished products meet international standards. All pasta is produced on branded Swiss and Italian equipment. This allows us to produce pasta with a hole inside, which is in great demand.

The gluten-free production line is located in a separate room, completely eliminating the unwanted contamination of gluten. Every stage of production is meticulously monitored by our specialists, and finished products are tested in the factory’s production and technical laboratory.

Our products

Мы стремимся предложить Вам наилучший сервис при работе с нашим сайтом. Для этого мы собираем и храним информацию о Вашем посещении сайта. Так называемые cookies. Файлы cookies не собирают и не хранят никакую личную информацию о Вас. Используя этот сайт, Вы даете согласие на использование cookies. На данном этапе Вы можете отказаться от использования cookies, настроив необходимые параметры в своем браузере.